The Importance of Insulation

Insulating steam and condensate equipment is important for several reasons, including:

- Energy efficiency: Insulation helps to reduce heat loss and conserve energy. By insulating steam and condensate equipment, less energy is required to maintain the desired temperature. Thus, reducing energy costs.

- Equipment protection: Insulation protects equipment from damage caused by extreme temperatures. In high-temperature environments, such as steam systems, insulation can help prevent equipment failure by lowering maximum allowable temperatures.

- Personnel safety: Insulation reduces the risk of personnel injury due to contact with hot surfaces.

- Condensate recovery: Insulation can help prevent condensate from cooling, which can lead to energy loss. By maintaining a higher temperature in the condensate, insulation can facilitate condensate recovery, helping to conserve energy.

Overall, insulating steam and condensate equipment is an effective way to improve energy efficiency, protect equipment, enhance personnel safety, and facilitate condensate recover

Flomar Ltd aims to reduce energy consumption and carbon emissions from the boiler room at the facility. Our report is solely concerned with the efficiency gains from Insulating Steam and Condensate Process Equipment and Pipework within the production facility.

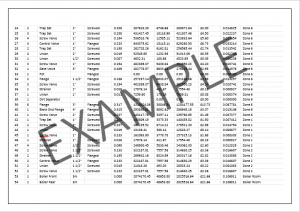

Once the survey has been completed, the data is collated into an easy-to-read report. This report not only outlines plant efficiency and any potential savings that could be made, but also calculates payback periods.

With rising energy costs and increasing demand to reduce emissions, can you afford not to? Let Flomar Ltd. improve your plant efficiency.