The Importance of Steam Trap Surveys

A steam trap survey is an important maintenance activity in industrial plants that use steam as a source of energy for their operations. Here are some of the benefits and importance of conducting a steam trap survey:

- Energy efficiency: Conducting a steam trap survey helps identify faulty steam traps that can cause energy loss and lead to increased energy bills. Fixing these traps can improve energy efficiency and reduce costs.

- Equipment longevity: Steam traps that are not working properly can cause damage to the equipment they are supposed to protect. A steam trap survey can help identify and fix faulty traps before they cause costly equipment damage.

- Safety: Faulty steam traps can be dangerous and cause accidents. A steam trap survey can help identify and fix these traps before they cause harm to people or property.

- Compliance: Some regulatory bodies require steam trap surveys as part of their compliance requirements. Conducting a steam trap survey can help ensure that your plant is compliant with those relevant regulations.

Overall, conducting a steam trap survey is an important activity that can help improve energy efficiency, equipment longevity, safety, and regulatory compliance in industrial plants.

Our Survey & Report

Available nationwide, we will attend site and undertake a steam trap survey on the steam system through the use of:

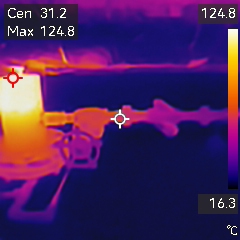

- Ultrasonic Testing Equipment

- Thermal Imaging Camera

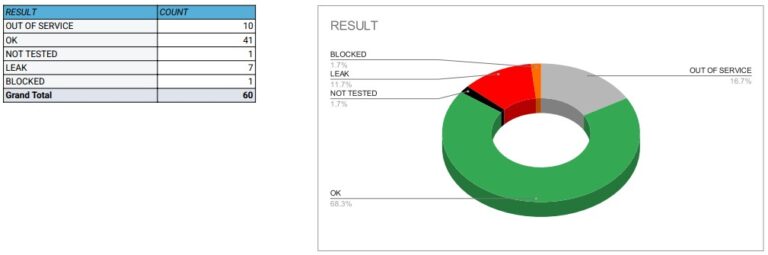

We will then spend time in our office, compiling a report – which will list the status for each steam trap tested; whilst also informing you of any monetary losses relating to each failed steam trap.

Each trap will be photographed to enable operators to easily locate their trap population.

The report is inclusive of a quotation for the supply of replacement steam traps; either supplied as direct replacements or more economical alternate units (if possible)

If you have any questions or wish to enquire about a steam strap survey, get in touch today.

Any information pertaining to site location and exisiting number of steam traps would be greatly appreciated.